Table of Contents

REF: Tools - 133

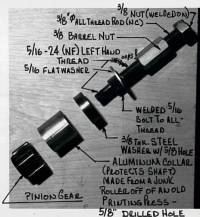

Pinion Gear, Pinion Shaft Runout Tools

Pinion Gear

90 and Prior Models (4 Speed)

|  |  |

| Homemade Pinion Gear / Removal / Installation Tools 1) | Homemade pinion gear press 2) | Pinion Gear Puller 3) |

|---|

|  |  |

| Large fender washer cut into a “C” shape and a gear puller | ||

| Homemade Pinion Gear Puller 4) | ||

|---|---|---|

|

| 3/8“ stainless steel plate with 20° spokes (for 18 teeth), sawed initial groove to depth and widened it with files |

| Homemade pinion gear locking tool for '89 models 5) |

|---|

91 and Up Models (5 Speed)

See also Oil Pump Drive Gear in the Evo section of the Sportsterpedia.

For turning the engine over using the pinion gear nut

| You can use a 15/16” wrench or deep well socket to turn the engine over using the pinion gear nut. 6) | |

|  |

| 93-Present Pinion Gear Nut (7916A) 7) | |

|---|---|

To remove or install the pinion gear nut

You'll need to lock the pinion gear from moving while turning the nut.

- It's very important to hold the crank on the pinion side with an appropriate pinion locking tool whenever you take the pinion nut off or put it on.If you hold the crank still from the primary side (or by putting the bike in gear and holding the brake), the twisting torque applied to the pinion nut gets transmitted through the crank, from one side to the other. The crank pin is not designed to resist much twisting force. You'll risk scissoring the crankshaft (knocking the crank out of true), which requires a full tear-down to fix. 8) So this is one of those situations where it's best to use the proper tool. 9)

Read the Origin of the Grindlock Tool here

| The Grindlock Pinion Shaft Locking Tool engages for the full depth of the pinion gear for max. strength. 10) | Due to a change in the pinion gear in 2000, there are 2 different versions of this tool: 1. (91-99) year models & 2. (2000 to present) year models 11) |

|

|  |  |

| Grindlock 91-99 & Grindlock 2000 (designed by XLFORUM member, “~Grind~” and Built by Hammer Performance 12). 13) 14) 15) |

||

|---|---|---|

Pinion Gear Runout

| Attach a scrap piece of metal to the outside of the gearcase and position a gauge holder on it so it won't move while turning over the engine. 18) | ||

|  |  |

| Install a dial gauge on the holder with the pointer on the pinion shaft. Find the lowest spot while turning the engine over and 'zero' the indicator. 19) | This setup is made with a piece of angle iron for the magnetic base to stand on 20) | |

|  |  |

| This gauge post is threaded into a cover mount hole. 21) | |

|  |

4)

photo by sevenyears of famine of the XLFORUM https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-era-specific-and-model-specific/ironhead-sportster-motorcycle-talk-1957-1985/175975-one-bolt-at-a-time-the-1960-engine-reassembly-thread/page10?t=1888378&highlight=pinion+gear+tool&page=10

6)

photos by Hippysmack

7)

photo by Hippysmack

13)

Left photo by aswracing of the XLFORUM https://www.xlforum.net/forum/vendors/hammer-performance/149240-pinion-gear-locking-tools-now-available-from-hammer-performance/page4?t=1618841&page=4

14)

Middle photo by Hippysmack

19)

photo by Grind of the XLFORUM